$39.99 Original price was: $39.99.$27.99Current price is: $27.99.

- Safe Payments, the Smart Choice

- Online customer care, always here for you.

- Worry-Free Shopping with Safe Payments

- 100% Quality Satisfaction

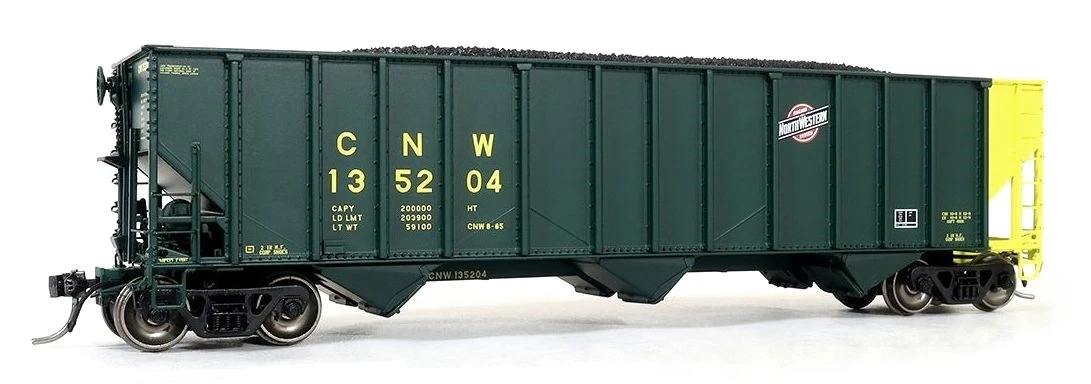

The mid-1970s brought about an urgent need for new coal hoppers based upon a combination of robust utility and export demand as well as an aging coal fleet composed of mostly smaller-capacity, 50 and 70-ton coal hoppers. Additionally, the opening of new low-sulfur coal mines in the Powder River Basin (PRB) region of Wyoming and Montana introduced a new supply of coal to the market, driving new coal hopper orders.

Pullman-Standard was one of several railcar manufacturers that addressed this urgent demand for modern “Triple” 100-ton hoppers with new designs produced in 1975-1976. While western and midwestern customers purchased Pullman’s 4000 cubic foot models, the eastern roads purchased Pullman’s 3526/3600 cubic foot hoppers, which effectively had shorter sides to accommodate higher density coal. We have produced both the “western” and “eastern” Pullman-Standard coal hoppers, and we offer models in multiple railroad-specific variations. The signature identifying feature for most of these cars? The distinctive Pullman “trapezoid” indentations on the flat panels (not all cars had flat panels, but most did).

Features:

Dimensional accuracy – designed from Pullman-Standard plans and verified with field measurements

Highly correct “true to life” colors

“Hyper-Accurate” lettering including exact fonts and lettering placement

“Near-scale” draft gear box with beautifully-rendered side “key” detail

Genuine Kadee scale couplers

Two different coal loads (one load is included with each model)

“See-through” brake platform

Full “lacy” AB brake detail and train air line

Rubber air hoses including “wrong side” mounting for rotary ends

Four dimensionally-correct coal hopper body variations with appropriate side panel arrangements (trapezoidal and flat), as well as offset and non-offset truck center arrangements

Five different assembly builds within our system, with more planned (Southern, for starters)

Road-specific details for each scheme, including different brake appliances and 2 different styles of unloading door mechanisms

Beautiful details – wire grab irons and coupler lift bars – no “molded on” plastic grab irons here!

Accurate interior bracing parts

All-New precision Tangent Scale Models 100-ton Barber S-2 trucks with roadname-specific rotating bearing caps and separate brake beam part

CNC-machined 36″ wheels

Replacement 36″ semi-scale wheels are available separately from Tangent in either blackened or nickel-silver finish

Kadee “scale-head” couplers

Be the first to review “Tangent Scale Models HO 24061-12 PS4000 100-Ton Triple Coal Hopper, Chicago And North Western #135285” Cancel reply

Related products

Trains

Centralia Car Shops N 7106-01 Superdome Passenger Car, Chicago And North Western “Powder River” #421

Reviews

There are no reviews yet.